Friction: Edition 19 | July 2024

FROM THE EDITOR

We are officially past the halfway point of 2024 and so far in Friction we have covered everything from Corporate Governance to Safety in Design to Numerical Modelling and Laboratory Testing. For this edition, we dive into raiseboring and how geotechnical investigation and thorough assessment is essential to reducing uncertainty and risk in the process, but must occur without compromising how findings are delivered.

To provide a lens into geotechnical raisebore investigations, we hear from Cartledge Mining and Geotechnics Senior Geotechnical Engineer, Phillip Quinn, who explores the vital role geotechnical engineers have in undertaking a detailed analysis of ground conditions, and why a solid working relationship between civil, structural and geotechnical engineers is essential across drilling projects to maintain safety and design integrity.

We also look to the upcoming events and what’s on the calendar for 2024 and beyond in the world of geotechnical engineering. Our events calendar has recently been updated to showcase the many brilliant conferences, abstracts and events taking place. Be sure to check it out to start planning your itinerary.

Regards,

Tim Cartledge

Friction is made possible thanks to our incredible contributors who offer up their valuable time to share knowledge and insights. Do you know a geotechnical engineer who’d enjoy Friction? Feel free to forward this email; share our news and features; and also direct them to our sign-up link here.

Deep diligence before the dig: How thorough geotechnical investigation lifts raiseboring safety and efficiency concerns

Raiseboring isn’t without its dangers. When dealing with large machinery on unsupported foundations, having a deep understanding of the processes involved in raise boring is crucial to ensure project safety.

In this article, Senior Geotechnical Engineer Phillip Quinn explores why geotechnical investigation is critical when incorporating raiseboring techniques on a mining project and proposes a more streamlined approach to the reporting system.

Updated Events Calendar

From Eurock 2025 to the Rocscience International Conference, there are ample industry events and networking opportunities taking place across the globe in 2024 and beyond.

So whether you’re based in Australia, Europe, Asia or the Americas, be sure to check out what is happening near you with our updated events calendar.

NEWS, PUBLICATIONS AND UPDATES

Challenges of shaft drilling in broken rock masses with a large raiseboring machine in confined underground space: A case study

When it comes to excavating shafts in broken rock masses, raiseboring machines can offer a safer, more efficient and cost-effective approach compared to traditional methods. However, there are limited investigations into its application for constructing large-diameter shafts in underground confined spaces.

In this study, Cong Zhang and Xu Liu establish a construction scheme for using large raiseboring machines in broken rock masses within underground confined space – demonstrating their effectiveness and benefits – at the Yili River Hydropower Station.

Soils in Geological Engineering

Soil is a prevalent material in all mining and construction projects. For geotechnical engineers, a thorough understanding of soil characteristics is crucial for evaluating mechanical behaviour, stability, and bearing capacity when considering safety on a project.

This article by the International Geotechnical Center delves into the importance of soils in geological and geotechnical engineering through the exploration of their characteristics, properties, and applications in the industry.

Wireless remote monitoring to mitigate slope risk

With safety front of mind, there is a growing need for streamlined risk management solutions, especially when it comes to slope failure. One way this can be managed is the integration of smart wireless monitoring technology.

This article explores how Senceive’s InfraGuard technology is being applied to open pit walls, mine infrastructure and tailings dams to monitor stability to ensure a safer and more stable environment.

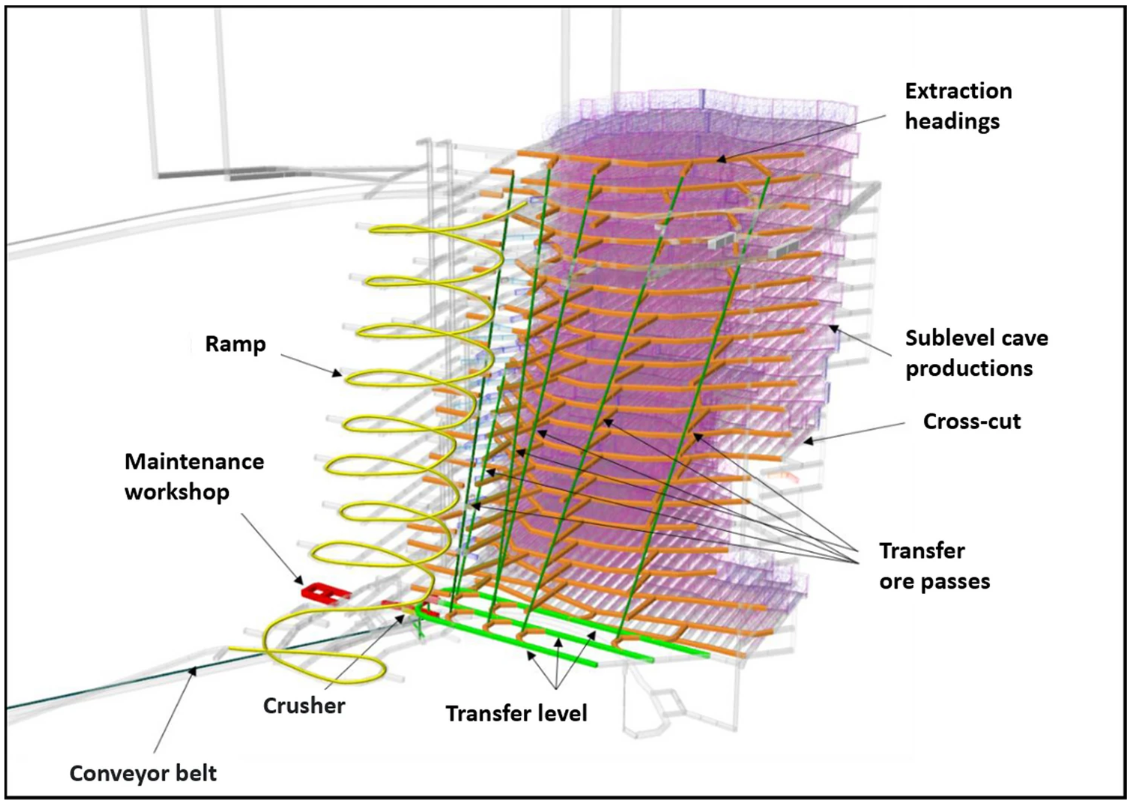

A review of the geotechnical design and optimisation of ultra-long ore passes for deep mass mining

Long ore passes have the potential to enhance efficiency in deep mines. However, there is currently limited data on optimal design and associated risk factors.

This article highlights the knowledge gaps in areas such as stability, construction methods, and material flow. It suggests the mining industry could benefit from further research to streamline long ore pass processes.

HAVE SOMETHING TO SHARE?

Friction is about connecting our industry together. If you have an article, paper or insight to share we'd love to hear from you. Find out how you can contribute to Friction here.