Why we use Slope Stability Radars and how it’s changing.

Paul Davies, Commercial Manager, Australasia GroundProbe Australia

In recent years, there has been a growth in the use of slope stability radars in open cut mines. Although the primary reason has always been operator safety, a secondary benefit to improvements to mine productivity has justified increasing their usage. In this article, GroundProbe’s Paul Davies shares the results of a survey of geotechnical engineers conducted in July 2023.

Identifying and mitigating geohazards are core elements of a geotechnical engineer’s role and gaining accurate insights into slope stability is critical on mine sites, where safety is of paramount concern.

Many tools exist to enhance monitoring and deliver precise, reliable, and real-time information to help better inform decisions and manage risks.

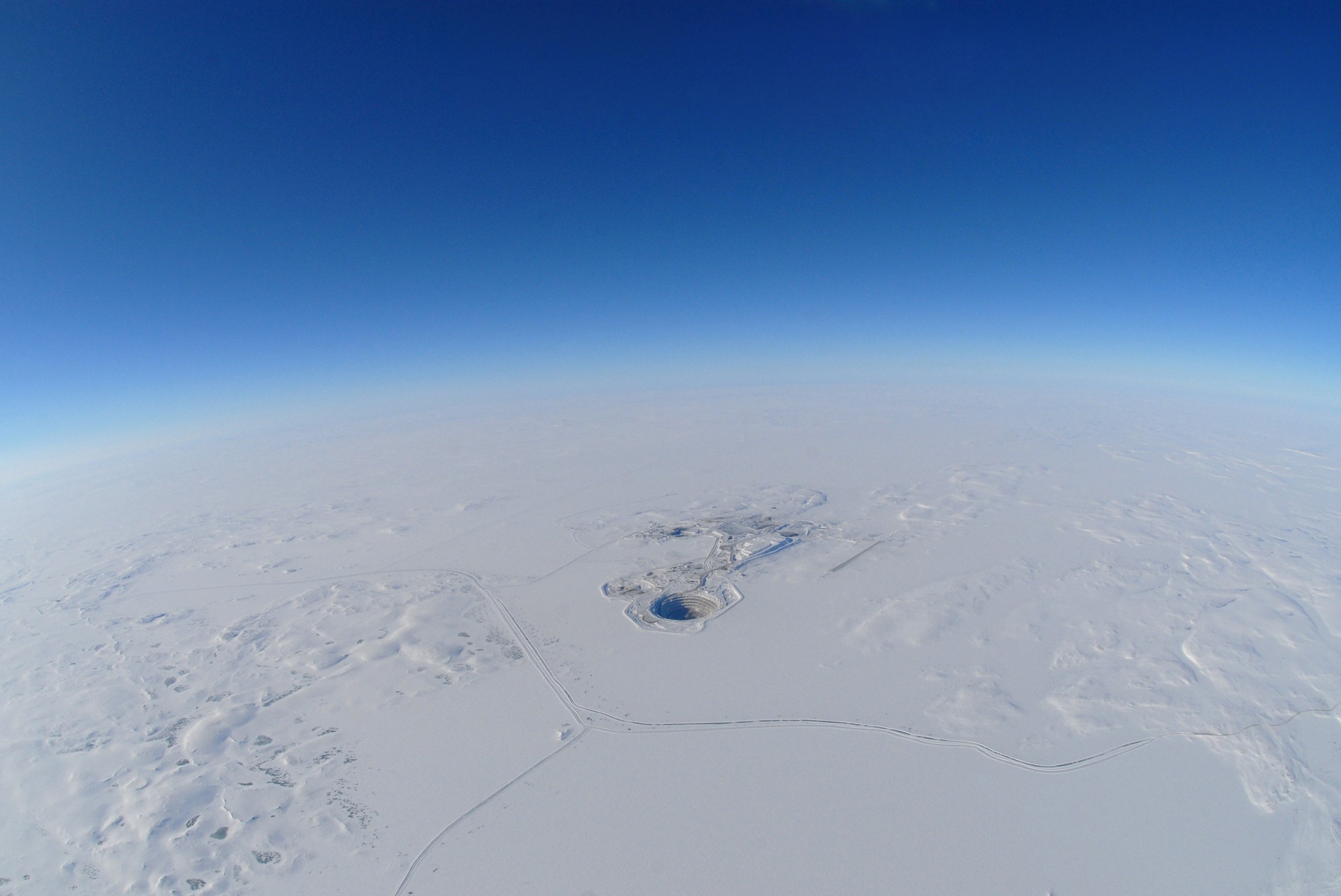

Radars are widely used as tactical and predictive safety monitoring tools across open cut mining environments. The ability to scan and monitor through dust, rain, and other weather conditions, which other technology solutions cannot, means they’re valuable across a mine site’s spectrum, from detecting new risks and hazards at long range, to monitoring tailings dams for breaches, and identifying and monitoring surface movement.

Homing in on a broader scope of use

In July 2023 we contacted hundreds of Australian-based geotechnical engineers for their perspective on why radars are being used. The results are illuminating.

Of the respondents, 34% were from the coal industry and copper, gold and iron ore constituted 62%.

A significant 84% of the respondents currently use radars in their day-to-day operations; with 100% identifying “safety and risk management” as their primary reason.

While unsurprising, it further solidifies the industry’s commitment to mine operator and equipment safety.

As one participant, Kyle Abbott of Talison Lithium said, “generally speaking the primary purpose of the radar is maintaining safety for mine operators”.

In addition, he further said, “however, once you have the radar there may be opportunities to support increased production”.

The recent survey supports this statement, with 60% of participants indicating an increase in radar demand monitoring, driven by the benefits of increased production.

Informed decisions are the best ones, and David Edwards of Meandu Mine says when there is no radar, safety measures must increase.

“When we don’t have radar, we need to increase the controls, such as increased stand-off during night shift and review higher risk jobs,” he says.

Physical controls and stand-offs in areas of production often incur a financial cost or affect productivity of the mine. Radars can provide information needed for tactical decision making on when and where to operate.

According to Philip Mather, of Regis Resources, “the radar monitoring allows us to confidently mine for longer underneath slopes that we know are moving and/or unstable, which reduces exclusion times and improves productivity. When instability issues occur within a pit the productivity gains provided by radar monitoring far outweigh the associated costs”.

“Additional insights into radar monitoring have helped with ongoing mine planning,” he says.

Leigh Bergin, from Stanmore Resources, employs radars across various situations and environments, both before the first shovel breaks ground and while mining is under way.

“We use radars in areas of higher risk, usually around faults/problematic structures (of low confidence), generally in background upon exposure to see deformation trends prior to coal mining,” he says.

“Additionally, if we have seen failure in previous strips, we’ll do a design change (reduce wall height and/or angle) and monitor wall upon exposure in background.”

Conclusion

When we consider why mines chose slope stability radars, very little has changed. They primarily support operator safety and mitigate risk.

However, we can see a movement of their wider adoption through supporting mining productivity.

One final reflection. As we seek to improve mine production through radars, we may observe as a by-product increased safety for open cut mining.